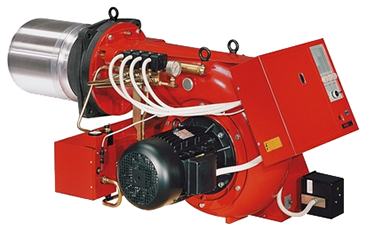

Three Stage Heavy Oil Burners

The PRESS T/N series of burners covers a firing range from 320 to 5130 kW. They have been designed in three versions for use in commercial and industrial installations, to burn different oil viscosity from 7 up to 60 °E @ 50°C. Operation is three-stage, thus making these burners suitable for installations that have variable but predictable heating requirements.

A servomotor adjusts automatically air damper to the opening value, determined to obtain always the necessary fuel consumption. Every model of PRESS T/N series is available in two different combustion head length (short or long head) to be selected on the basis of specific application requirements. An electric preheater has been fitted to maintain the oil at the correct atomising temperature at maximum output and special heaters kits are separately supplied for burning high viscosity oil.

Simplified maintenance is achieved by the Riello designed slide bar system, which allows easy access to all of the essential components of the combustion head.