Gas-fired, central heating only, electronic ignition

Light oil fired, with 95 litre DHW calorifier

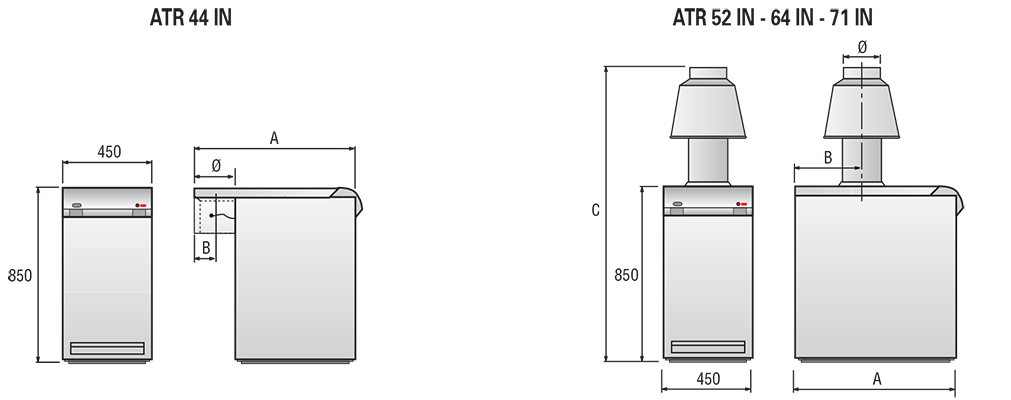

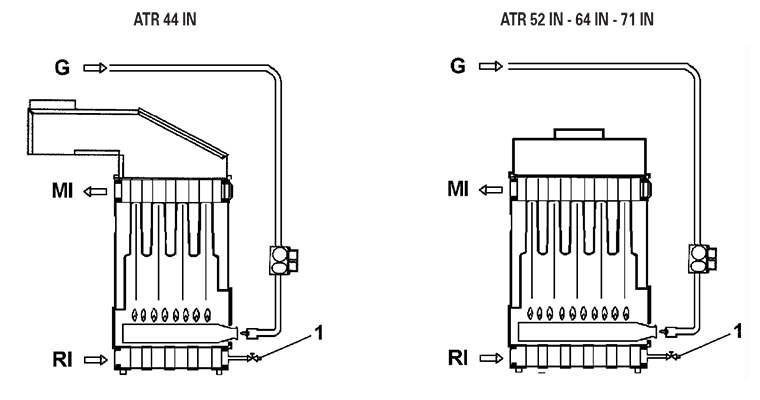

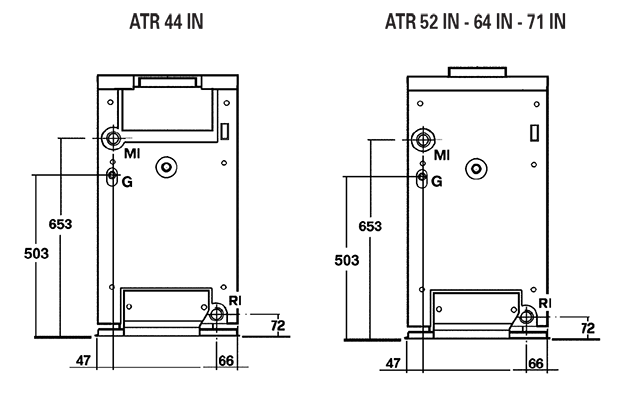

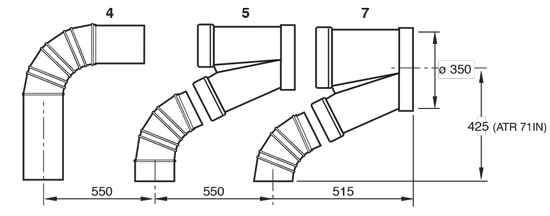

High efficiency boilers designed heating large domestic application. Ideal for installation in any boiler room. Cast-iron boiler body with stainless steel atmospheric burner, stabilised flame and ionisation control. Total shutdown function and completely protected control panel. For the production of domestic hot water, the boiler can be combined with the ATRB calorifier or any other calorifier; a kit can be fitted to use an electronic temperature controller. Available in 4 open flue versions. Duties from 43.6 to 71.1 kW. The ATR boilers can be installed in modules of two or three boilers: this solution ensures high-efficiency capacity control and division of the thermal load on each boiler.

Product advantages

- Ideal for the heating requirements of large utilities.

- Can satisfy domestic hot water requirements in combination with Riello ATRB calorifier

- Management of (up to three) multi-zone systems using the special accessory kit. Boiler cascade operation available as optional.

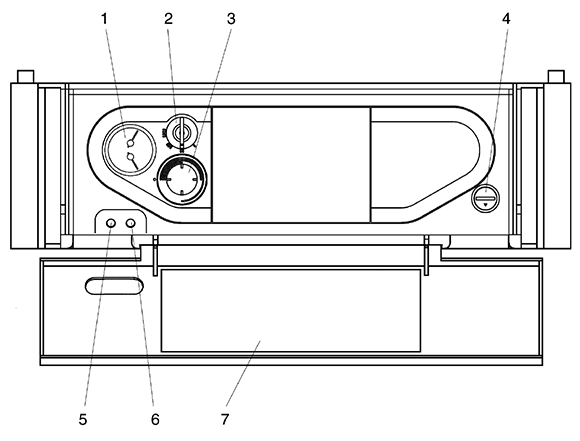

- Built-in panel for temperature control functions.

- LPG kit, available as optional.

Installation/maintenance advantages

- Control panel connected using the special kit to any calorifier or regulation temperature controller. Electrical maintenance from the front: wiring on the terminal block that is easily removable from the new control panel.

- Index of protection of control panel IP40.

- Reset function and alarm messages directly on the control panel.

- Gas cock supplied. Built-in gas pressure stabilizer. Completely protected control panel.

- Ready for connection to a room thermostat and a central heating system pump.