Cast iron atmospheric boiler

Gas fired, central heating only, electronic ignition

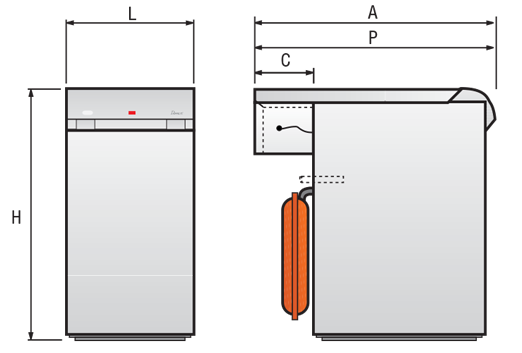

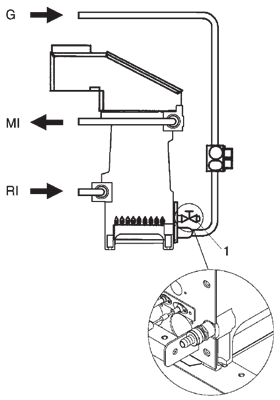

Domus IN: open flue

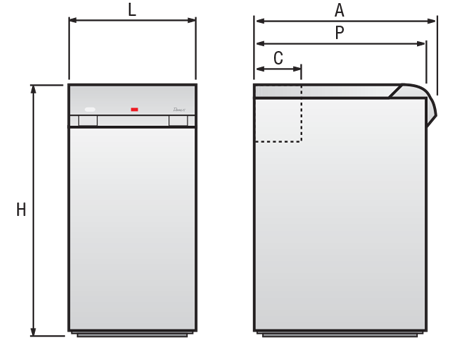

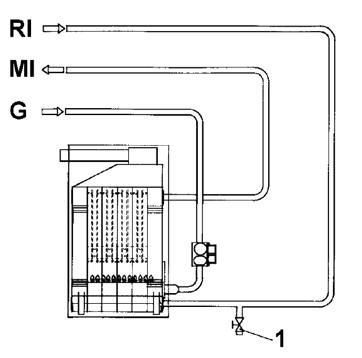

Domus ISN: room sealed

High efficiency cast iron boilers designed for central heating, with low running costs and reduced emissions. Available in a natural open flue version and room sealed version. The open flue version is supplied with a brand new high performance combustion unit. Automatic ignition system supplied with atmospheric burner. LPG conversion kit supplied as standard.

Product advantages

- Innovative stylish design, for installation even in domestic rooms like kitchens, washrooms and utility rooms.

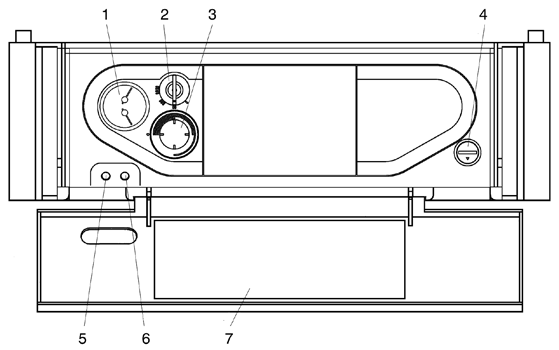

- New, stylish, and user friendly control panel.

- Optional Riello Esatto digital temperature control system to be fitted on the control panel with pressure gauge. Multi-zone central heating kit (up to a maximum of three zones) available as optional.

- Boilers can be connected to a Riello ATRB 120 DHW calorifier (or equivalent) and to a temperature control system using the relevant kits.

Installation/maintenance advantages

- Easy inspection of the flue and of the air box in room sealed versions.

- In room sealed versions, the air box is fitted with combustion control sockets as standard.

- Front access to the control panel with removable electrical terminal block.

- Index of protection of control panel IP X0D (IP 40).