Manifold with Flowmeter

Chrome-plated brass modular supply manifold.

- Flowmeters and flow-rate balancing valves

- Interchangeable sizes for copper, plastic and multilayer pipes

- Connection: 1” – 1” 1/4 male-female

- Centre line between ports: 50 mm

- Available with 1/2” or 3/4” eurokonus connection, art.3980

Description

The Flowmeter is a device designed to control, measure and monitor the flow distribuited to each terminal within a heating and/or cooling system. This is possible because it is a combination of lockshield valve to control the flow of fluid in the circuit, and flowmeter to measure the quantity of fluid in the circuit (l/min). This makes for easier installation and system adjustment, reducing overall costs. Manifolds equipped with flowmeters should be installed on the supply pipeline (on underfloor heating systems); they ensure fast, accurate system balancing and thus optimised energy distribution.

Installation

Manifolds equipped with a flowmeter can be installed in either vertical or horizontal configuration.

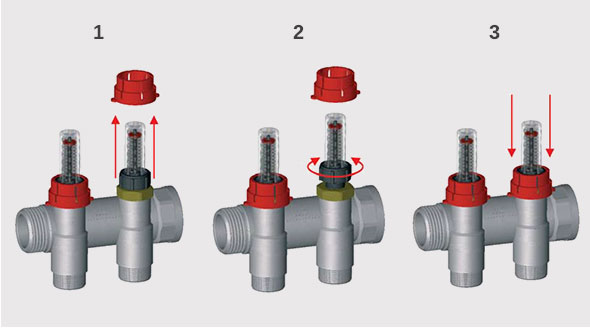

Installation should proceed as follows:

- Assemble manifolds to create a distribution unit

- Totally open both the flowmeter and the corresponding valve on the return manifold (keeping any other flowmeters closed). Activate flow to the system and bring it under pressure, leaving water circulating in the pipeline to protect the individual circuit from any air released into the pipes. Repeat the process for all circuits to ensure complete system deaeration

- To carry out system balancing, adjust the flowmeters on each circuit by rotating the regulating valve

- Lock the set position with the correct anti-tampering device