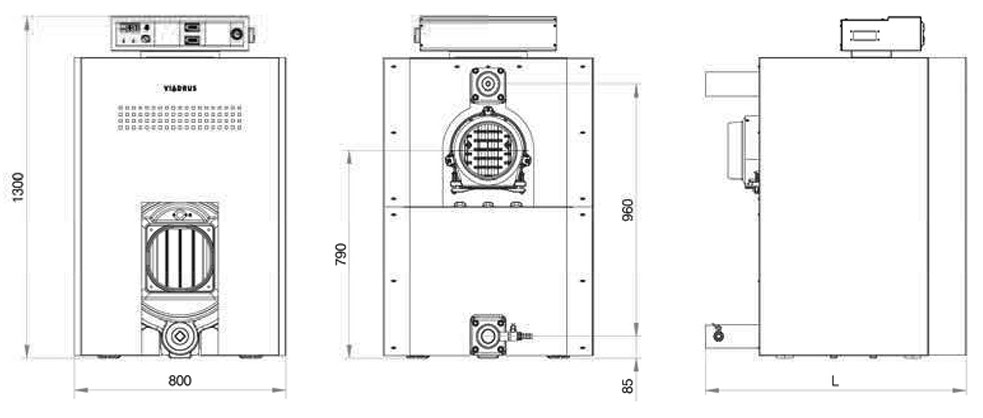

Cast-iron boiler for jet burner

Advantages

- long service life of cast-iron boiler block

- high burning efficiency for all fuels

- economical operation

- delivery including the burner (on demand)

- fully automatic two-stage output operation for selected burner

- operational status signalization or operational data transfer for outer loop control

- boiler control by thermal sensor or by outer loop control

- delivery of assembled or disassembled boiler according to order

- customer choice left or right opening of both closing and burner plate

- easy access of sight hole and combustion chamber overpressure measuring point

- cascade operation by outer loop control

Fuel

- natural gas

- heating oil

- biogas

- heating oil

Boiler output (according to size and fuel)

92-320kW